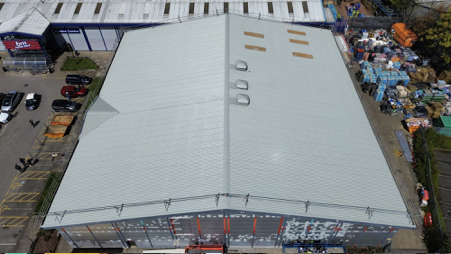

Full Roof and Cladding Refurbishment – Retail Unit, Dunstable

Case Study: Full Roof and Cladding Refurbishment – Retail Unit

Location: Dunstable

Project Type: Roof & Wall Cladding Refurbishment

Completion Date: May 2024

Duration: 8 Weeks

Project Overview

We were approached to carry out a complete refurbishment of this retail unit’s external envelope. The unit was suffering from a combination of roof degradation, inefficient water management, and visible cladding damage. Our objective was to restore functionality, improve weather resistance, and give the building a revitalised, professional appearance in the branded colours.

Scope of Works

- Spray coating of the roof - to restore waterproofing and extend lifespan

- Gutter lining system - to address water ingress and drainage issues

- Wall cladding repairs - including dent and hole restoration

- Full spray painting of the wall cladding - to enhance aesthetic appeal and provide long-term protection

Process

1. Roof Spray Coating

The roof surface was first cleaned, cut edge corrosion treated/sealed and fixings encapsulated before a polymer coating was applied via airless spraying. This method ensured a uniform, durable finish that offers excellent resistance to weather and UV exposure.

2. Gutter Lining Installation

Existing gutters were cleaned, inspected, and lined with a high-performance membrane system designed to seal joints and prevent future leaks. This solution greatly improved water flow and protection against overflow and corrosion.

3. Cladding Repairs

The external wall cladding showed visible dents and holes. These areas were thoroughly repaired using high performance filling compound, sanding, and panel reshaping techniques to ensure a smooth finish suitable for repainting.

4. Cladding Spray Painting

After repairs, the entire building was coated with a high-grade cladding paint system using airless sprayers. The result was a uniform, colour-consistent surface with enhanced weather resistance and improved kerb appeal.

Materials & Equipment Used

- HD Sharmans Delcote roof coating - UV stable, weatherproofing

- HD Sharmans Seamsil – cut edge corrosion

- Weathfold gutter lining system - reinforced membrane

- HMG Synergy V12 cladding paint - in client-specified colour

- Airless spray equipment for both roof and vertical cladding

- MEWPS – for safe access to the working areas

Challenges & Solutions

- Shop fit out: All works were carefully scheduled to work alongside a full shop fit out.

- Cladding Damage: Heavily dented panels were restored rather than replaced, saving time and cost.

- Weather Considerations: Dry weather windows were used strategically to ensure product curing.

Results

- A fully restored, watertight roof with extended lifespan

- Efficient, leak-free gutter system

- Modern, clean, and professional appearance of the building

- Enhanced durability of external surfaces against weather and wear